Applications

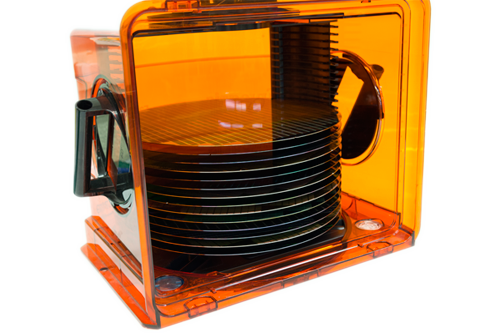

FPC Connectors

High-temperature nylon plays a crucial role in FPC connectors. Due to its excellent heat stability and chemical resistance, it can be used in high-density electronic connectors for SMT processes in high-temperature and high-density electronic connectors.

High-Temperature Structural Components

High-temperature nylon is used in high-temperature structural components such as engine parts, heat treatment equipment, and high-temperature sealing components. Its ability to maintain stability under extremely high temperatures makes it suitable for applications that require resistance to high-temperature heat deformation.

Aerospace Application Connectors

In the aerospace sector, high-temperature nylon is widely used in connectors and components due to its ability to withstand extreme temperatures and environmental conditions.

Water Treatment Applications

In water treatment and chemical industries, the corrosion resistance, high-temperature stability, and low moisture absorption of high-temperature nylon make it a choice for equipment such as pipes, valves, filters, etc.

Healthcare

High-temperature nylon is also gaining significant attention in the medical device and healthcare sector, especially in applications requiring high-temperature and chemical resistance.